The Definitive Guide to Motorcycle Parts New Zealand Specialists

Wiki Article

Some Of Motorcycle Parts New Zealand Specialists

Table of ContentsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.The Facts About Motorcycle Parts New Zealand Specialists RevealedHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.Some Known Facts About Motorcycle Parts New Zealand Specialists.Motorcycle Parts New Zealand Specialists Can Be Fun For EveryoneWhat Does Motorcycle Parts New Zealand Specialists Do?Unknown Facts About Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Mean?

So, connect to one of our professionals today.CNC machining innovation is rapidly coming to be the focal point of several manufacturing processes around the globe as a direct result of its several advantages over various other techniques. Furthermore, the industries that produce bikes have actually obtained on board with this trend. The most cutting-edge companies are currently creating their engine elements and wheels using machining strategies originally developed for motorbike components.

On the other hand, the effects of market are the key emphasis of this article. Let's obtain straight into it. You might be questioning why we use. It is not difficult to fathom the variables that led to this result. Currently that we have your focus allow us discuss the reasoning behind this modern advancement in the bike manufacturing sector.

Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

In addition, you have total control over the look of the parts, also down to the minute information. Periodically, motorcyclists might choose to spruce up their ride by setting up aftermarket components or changing the bike's makeover.

The 9-Minute Rule for Motorcycle Parts New Zealand Specialists

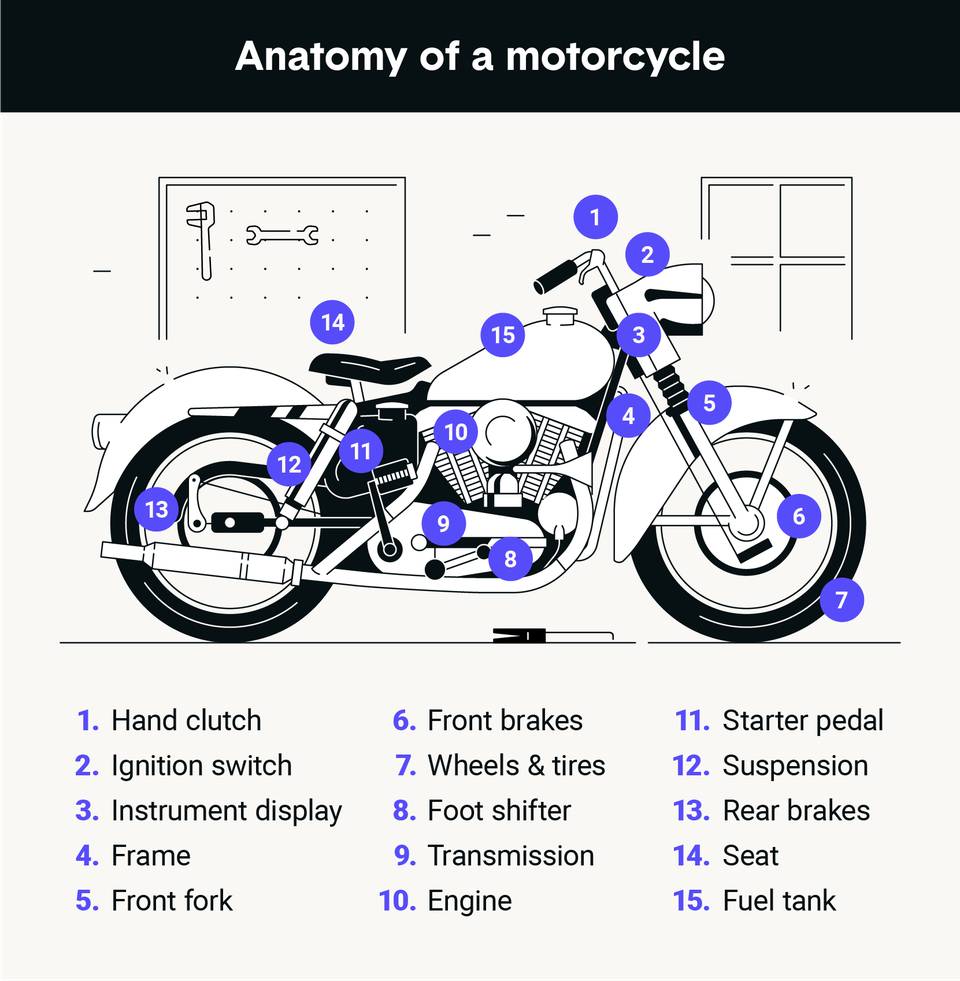

CNC machining may be used to make nearly all of a motorcycle's metal and plastic components. To continue, we'll discuss a number of machined components for bikes.Milling procedures are made use of to acquire the wanted degree of wheel customization. Another element of the motorbike that might be customized is the tires.

Some Known Details About Motorcycle Parts New Zealand Specialists

When it comes to a lorry (or a motorbike), the most essential component is the engine. Several individuals mention it as the "heart" of the automobile. On the various other hand, the camshaft, the cyndrical tube head, and the pistons often tend to be detailed and need layouts with a high level of precision.Use only high-quality products, however, considering that these lights are vital for the safety of motorcyclists and other vehicle drivers or people on the road, particularly at night. Motorcycle headlights have three primary parts: the light bulb, or light resource, the lens, and the housing.

Milling procedures with a remarkable surface would certainly result in the lenses having a reflective top quality that is similar to that of a mirror. The cover, on the other hand, is not made up of delicate products; rather, it is created out of difficult polymers that can be machined into even more elaborate patterns.

The Greatest Guide To Motorcycle Parts New Zealand Specialists

Bike manufacturers frequently cast these components, yet just for the production of bespoke components. Machining on five axes in today's world is the means by which any style shape may be realized.The success of the procedure is contingent on the mill cutters' capacity to calculate refined and complicated angles properly. published here Choose Runsom for your personalized motorcycle components! We have the ability to produce difficult and trendy elements making your motorcycle matchless. Many are crafted from aluminum or steel alloys, each of which has its usages and advantages.

Below are a couple of examples of metals usually made use of in bike element machining. Light weight aluminum is the main product made use of by companies specializing in producing custom bike parts to produce a lot of these parts. In the past, we would construct our engines out of cast iron. On the various other hand, aluminum is rapidly ending up being the material of option, partly due to the truth that it is more light-weight.

Zinc refers to one more metal that is very light in weight and has fantastic machining top qualities as a result of its high mechanical stamina. This product might be created into virtually any kind of form and preserves its measurements well. Even mission-critical parts that require a high degree of accuracy may gain from their usage.

A Biased View of Motorcycle Parts New Zealand Specialists

Another steel that sees heavy usage in the production of CNC-customized elements is magnesium. It is among the lightest steels that are currently easily accessible and has excellent machinability features and strength appropriate with its low weight. One of the disadvantages of magnesium is that its dust may conveniently ignite.

Because of its remarkable machinability and weldability, stainless-steel is an alloy that is particularly fit for CNC procedures. They have great deterioration resistance and a high aesthetic allure. Their most typical usage in producing various bike elements is fasteners, such as screws and bolts. Their low sensitivity to oxidation and deterioration makes them excellent for this usage.

Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

It seems that CNC transforming and crushing go to the website are the fundamental processes. In addition, it calls for keeping bars of product, most usually plastic or metal, in position and then turning a reducing tool to remove areas of the material as the product is transformed.

These techniques are equally crucial and generate parts with high precision and regular high quality. The procedures aid enhance the overall quality of the machined bike components.

The Definitive Guide to Motorcycle Parts New Zealand Specialists

Report this wiki page